Forging the Future: Smart Manufacturing Use Cases

There is no doubt that smart manufacturing is delivering efficiency. Whilst robotics and automation have taken process modernisation so far, some dynamic efficiency advantages are being unearthed through the application of data and AI. Bill Primerano– IBM Global Data & AI Technical Specialist, and Brendan Hoo– IT Business Analyst at Tata Steel, UK spoke to us about the top five ways to put data to work in manufacturing.

1. Sustainability – As the World Economic Forum highlights, “The aim is to radically reduce the carbon footprint of the manufacturing industry by sharing and exchanging data across supply chains,” setting the stage for a greener future.

Sustainability is no longer just a buzzword—it’s the foundation of forward-thinking manufacturing strategies. Leading companies are moving far beyond mere compliance and are embracing green initiatives to slash carbon footprints while driving lasting value and enhanced profitability.

As one of the biggest energy users, driving energy efficiency in manufacturing is delivering the greatest gains. As the adage goes, you can’t manage what you don’t measure, and data collection and analysis is revealing opportunities to drive efficiency. From recycling materials to minimising waste and enhancing energy efficiency, these initiatives don’t just protect the planet—they also boost profits.

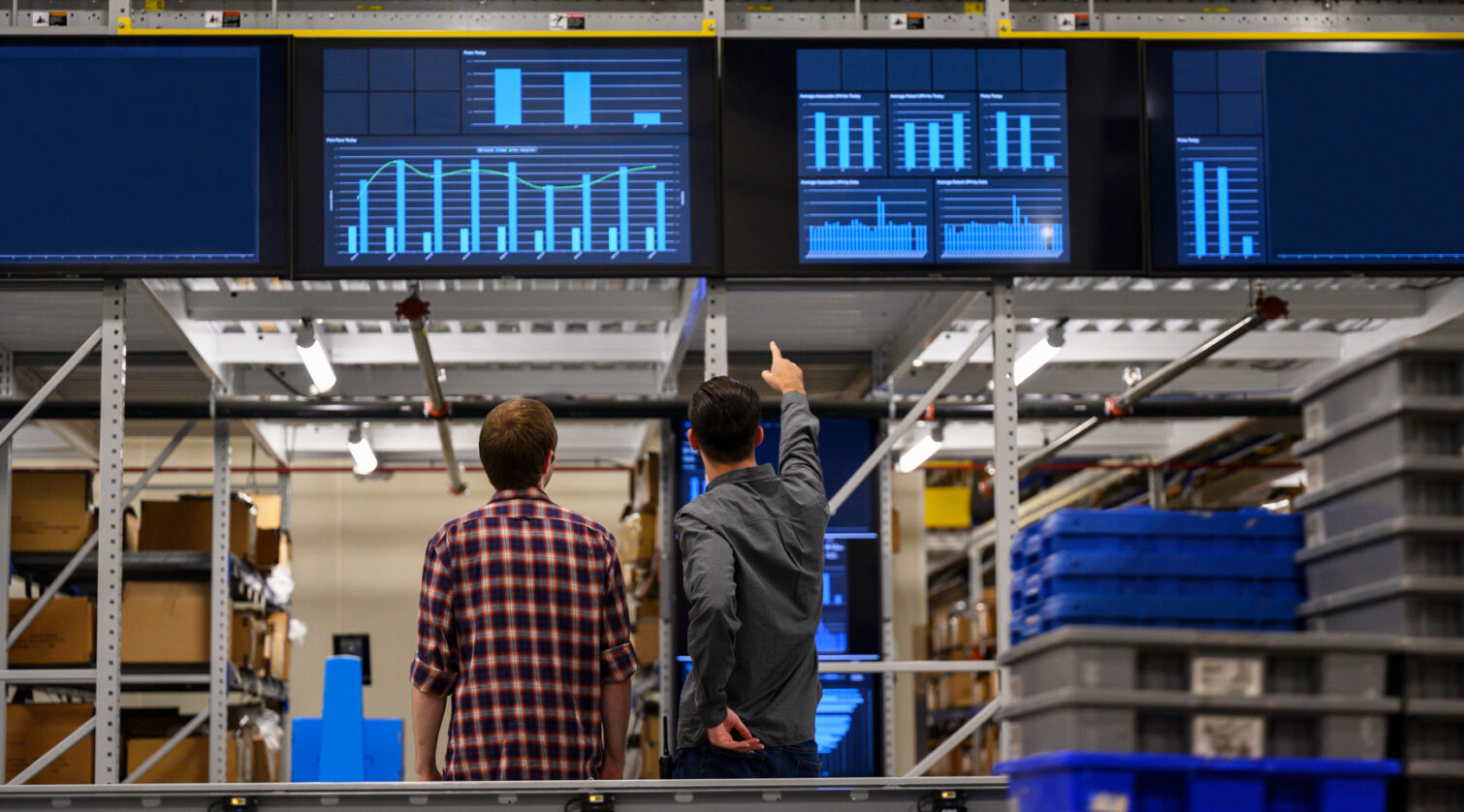

2. Big data for predictive maintenance – The integration of IoT (Internet of Things) into manufacturing environments isn’t just an upgrade—it’s a game-changer. With real-time monitoring and data collection, companies are harnessing the power of big data for predictive maintenance, slashing downtime and optimising performance.

Automation and robotics are revolutionising production lines, delivering unmatched precision and reducing labour costs. As industry leaders put it, “Manufacturing is on the brink of a data-driven revolution, where hyperconnected value networks and data analytics drive new levels of efficiency and productivity.”

Welcome to the age of digital transformation, where data and connectivity reshapes how manufacturers operate.

3. Resilient Supply Chains – As one expert rightly puts it, “the conventional approach to resilience is seriously flawed. Many companies follow a boom-and-bust pattern, making big investments in resilience after a supply chain disruption and then paying little attention to the issue until the next crisis.”

But resilience is about much more than reacting to challenges. With real-time analytics, companies can identify weak points in the process before they escalate into full-blown crises. By integrating data from multiple sources, companies can gain the visibility needed to adapt to changing conditions in real time. Whether it’s identifying alternative suppliers at the first sign of trouble or collaborating seamlessly with stakeholders. Data is the key to navigating risks and keeping operations smooth—no matter what challenges arise.

4. Modern production processes – Innovation drives progress in manufacturing, pushing companies to break new ground and outpace the competition. With significant investment in research and development, the industry is embracing transformative technologies like additive manufacturing (3D printing). These breakthroughs aren’t just futuristic—they’re here now, enabling the production of complex parts faster, cheaper, and with less waste. As smart factories become the new standard, companies that harness these advancements will lead the way into a more efficient and agile future.

5. Building Tomorrow’s Workforce – A company’s greatest asset in the ever-evolving manufacturing world is its people. As the landscape shifts, investing in human capital is essential to staying ahead. Companies are equipping their workforce with the skills needed to meet today’s challenges by ramping up training and development programmes. By nurturing talent and focusing on skill development, businesses are creating a resilient workforce ready for whatever comes next.

Case Study

Tata Steel Navigating Supply Chain Disruptions

We live in a world of constant supply chain upheaval. From global events to labour shortages and inflationary pressures, businesses have been hit hard. The key to not just surviving but thriving in these turbulent times is robust analytics and scenario modelling. Companies that leverage technology to quickly adapt to shifting market conditions and learn from industry leaders are the ones that stay ahead.

Top organisations are using integrated data across finance and operations to make faster, smarter decisions. Integrated business planning, extended planning, and analysis are no longer optional—they’re essential. This cutting-edge approach connects the dots between sustainability, workforce planning, and market forecasting, giving companies the agility they need to succeed.

Leveraging the Latest Technology

Today’s advanced analytics are a game-changer for supply chain operations. Take IBM’s planning analytics: this all-in-one solution doesn’t just integrate data from various sources—it delivers powerful capabilities like workflow automation, self-service dashboards, and scenario modelling. Deployed by over 7,000 organisations globally, it enables quick, accurate calculations and analysis. With built-in predictive and prescriptive analytics, it empowers businesses to make smarter decisions, faster.

Tata Steel’s Journey: Transforming with Planning Analytics

Brendan, Senior IT Business Analyst at Tata Steel UK, shared the remarkable transformation his company has undergone since embracing planning analytics in 2020. The road to success wasn’t without its challenges, but the results speak for themselves.

The Starting Point: Overcoming the 2020 Challenges

Tata Steel UK found itself grappling with a complex order book and inefficient production scheduling, relying heavily on outdated manual processes and endless Excel spreadsheets. Something needed to change.

Key Implementations

- Planning and Scheduling Manufacturing App: Tata Steel integrated this app with its ERP systems, updating production schedules every 30 minutes. Real-time data management became a reality, giving teams total visibility of their order book and control over master data—no more flying blind.

- Commercial Demand Planner for Distribution: With daily updates of invoice data, this planner empowered Tata Steel’s commercial teams to adjust forecasts in real time. It wasn’t just about reacting—it was about anticipating.

Game-Changing Benefits

- From Solo to Collaborative: The move from single-person planning to multi-user applications revolutionised the way teams work together, improving collaboration and efficiency.

- Time Saved, Data Enhanced: Automation took over tedious data collection and prep, giving teams more time to focus on decision-making while boosting data quality.

- Agility at Its Best: Tata Steel’s ability to replan swiftly in response to changing market conditions gave it a serious edge.

The Road Ahead

Fast forward to today, and Tata Steel has scaled up to 10 applications, with more in the pipeline. Each new development is faster, more efficient, and part of an integrated planning cycle. AI forecasting and optimisation are now on the horizon, promising even smarter decisions and better outcomes.

Conclusion

Sustainability, digital transformation, and continuous innovation aren’t just trends—they’re the pillars of success in the manufacturing and supply chain industries. Combine that with investment in human capital and strong partnerships, and companies can build the resilience needed to thrive in this fast-changing world.

Want to see these strategies in action? Dive deeper into Tata Steel’s transformation—watch our on-demand webinar and discover how you can bring these innovations to your business.